Safe Room Walls

Bullet And Attack-Stopping Wall Panels

HOW Standard WALLS ARE VULNERABLE

Firearms

Even low-level calibers easily tear through wood or steel stud walls.

Fires

Though meeting basic code standards, walls provide little flame protection.

Sharp Weapons

Axes, sledgehammers, and makeshift battering rams can easily penetrate drywall.

Storms

Projectiles from hurricanes and tornadoes send massive shrapnel to homes.

The standard 2×4 walls that make up the vast majority of rooms are surprisingly easy to break through, whether steel or wood studded. When building a safe room, many people focus on the entrance and forget to reinforce their walls.

Every part of a standard wall is susceptible. The drywall between studs is filled with not much more than air and, perhaps, some wires. A simple hammer or even a steel-toed boot could easily puncture through.

Wood or steel studs provide some resistance at those points, but not much. Wood can easily be drilled through or sliced with an ax. Steel studs form from denser material (metal), but force can easily bend them because they are hollow and lengthy. Further, even a low-caliber bullet would easily tear through either one.

Traditional Safe Room Wall Materials

Modern Safe Room Wall Materials

Materials

Poured-in-place concrete, concrete block, and high-density steel, such as AR-500

Advanced materials such as ballistic fiberglass and Kevlar (para-aramids).

Installation

Concrete typically is only able to be installed during a new build. Steel is impractical to cut on-site, so builders must perfectly plan dimensions.

Ballistic materials easily install into new or existing walls (wood or steel framed). The material comes in numerous standard sheet sizes, and installers may cut it on-site with diamond-grit saw blades.

Protection

Not officially rated for ballistics due to the product’s non-standard nature, but determined by experience. Excellent forced entry resistance.

Panels rated with UL certification for bullet resistance to all 8 Levels. ASTM rating for fire & forced entry resistance. Consistent product.

Modern Materials Specialized For Safe Rooms

Specialized Features:

- Does not produce shrapnel

- Doesn’t impede emergency signal

- Blends in to walls

- Complimentary 3D modeling to plan layout

- Easy, modular install on site

MODULAR VAULT WALL OPTIONS

We work with three main options depending on the situation.

Handgun Protection Only

Resistant to Forced Entry

Can be cut on-site

1 Standard Sheet Size

Resistant to Fire

1-2 lbs. / Square Foot

Flexible, Bends Easily

All U.L. 752 Bullet Resistant Levels

Class IV ASTM Forced Entry Rated

Cut on Site With Diamond Grit Blade

9 Standard Sheet Sizes

ASTM 60 Minute Fire Resistant

3 – 15 lbs. / Square Foot

Rigid, Minimal Bending Possible

Handguns (Soft) & Rifles (Rigid)

Not Designed for Forced Entry

Can be Cut Similar to Wood

Made-to-Order Sizing

Melts At High Temperatures

1 – 1.5 lbs. / Square Foot

Soft Material Option Bends Easily

Concrete Safe Room Walls

Concrete is a solid option during a new home build, particularly if the concrete will be used elsewhere in the structure: concrete provides thick structural support.

Options include poured-in-place concrete and concrete-filled block masonry. In recent years insulated concrete forms (ICF) blocks have become increasingly popular. Builders almost always integrate Rebar (reinforced steel bars) into the concrete for significant tensile strength improvements.

Benefits

Concrete and masonry options provide some of the best forced entry protection. We expect them to withstand a wide range of bullets fired.

Downsides

There are several issues in using concrete for a safe room.

- If not installed during a new home build, it is not practical to get poured-in-place concrete to an existing room.

- A concrete room requires proper support (ground level or basement) to be structurally sound – this is problematic when clients plan their safe room for an upper-level bedroom floor.

- Making modifications for electricity, HVAC, and other cut-outs in a masonry wall is challenging.

- We expect concrete to provide a fair amount of protection, but since it is not a standardized product, there is no ballistic testing to know what level of safety a concrete room truly achieves.

Ballistic Steel Panic Room Walls

High-strength steel, such as AR-500, has become a prevalent material for ballistic targets and body armor. Some clients consider integrating steel in their panic room walls, as well.

Benefits

Ballistic steel can be very thin relative to its bullet-stopping strength. It provides outstanding protection from cutting attacks, too.

Downsides

There are several factors related to panic rooms that make steel a mediocre wall option.

- The steel is nearly impossible to modify on-site. A slight mistake in sizing means a contractor may have significant problems during installation. Attaching the panels is problematic even.

- There is no official rating on ballistic steel’s ballistic properties for walls, just various people’s experience.

- Though steel is thinner than other ballistic materials, the weight is generally no less than cheaper options.

- Steel walls block cellular and Wi-Fi reception – a considerable risk for a panic room where family members need to contact police during an emergency.

Protective Rating Of Our Wall Panels

Bullet Resistance

Stops multiple rounds of bullets fired from handguns, machineguns and rifles.

Forced Entry Resistance

Protection from axes, hammers, mauls, acetone, blades and more.

Fire Resistance

Rated for 60 minutes of fire resistance in a wall assembly.

Storm Resistance

Blast Resistance

Accoustical Resistance

Thermal Resistance

Select Products Rated or Tested By:

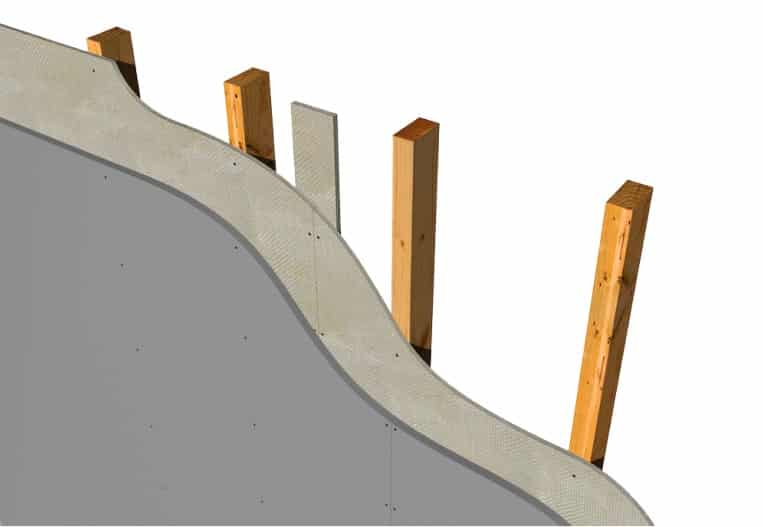

Installation of Modular Safe Room Walls

There are numerous ways to reinforce panic room walls during construction and afterward. Almost any type of reinforcement can offer significant gains over standard drywall.

Panels Are Easy to install

Panels come in convenient sizes similar to drywall. They can be pre-cut to fit your space. They easily attach into existing studs – even if drywall is in the middle.

Secure Walls Blend in

Walls containing ballistic fiberglass or Kevlar look just like standard walls. You can place them inside the wall for complete hiding or attach them to the face of a wall to be painted or paneled.

If you have the advantage of building a new home, there are a wider variety of options. You can add the precise sizing of the room and walls needed into your building blueprints, have access to the walls from all directions, and have the contracting professionals on staff who can implement any plan at this point.

Creating walls that incorporate high-security panels is almost the same as building ordinary walls. Rather than leaving the space between drywall hollow, fill it with ballistic panels. Fabric armoring includes Kevlar and ballistic fiberglass panels.

We offer vault wall panels in 9 standard sizes and can make custom sizing. Panels install on your wall studs in the same way drywall sheets install.

Our team at Fortified Estate will work with your contractor to identify quantities and dimensions needed.

Just because you have an already built home does not preclude installing highly secure panic room walls.

Saferoom wall panels are modular pieces of sophisticated materials such as Kevlar. We offer them in standard wall panel sizes, such as 48″ x 96″. These wall panels can be applied directly to the interior of your safe room or panic room walls.

No wall demolition is needed. Clients order sheets of fiberglass panels directly to your home. A contractor – sometimes even the homeowner – uses self-tapping drywall screws to secure the panel wood/metal studs embedded inside the wall. The addition adds merely 0.25″ – 2.0″ of thickness to the wall, depending on the armoring level selected.

To finish the vault walls’ interior, installers either paint the bulletproof panels, adhere a layer of veneer, or place another layer of drywall on top of them. When clients place an additional layer of drywall on top, they attach it by driving self-tapping drywall screws through the sandwiched armored paneling into the wall studs. The material has enough sheet strength to support the weight of both.

FREQUENTLY ASKED QUESTIONS

Many people use their safe room as a large vault for valuables, most commonly for firearm collections.

Proper vault walls are similar to building panic room walls, with some minor differences. Many of the same factors are present, and their uses overlap: most clients utilize the same vault room to protect valuables and as a panic room in emergencies – to protect people. Therefore, vault walls have similar objectives to panic room walls.

Vault walls must rigorously protect from forced entry, first and foremost. Generally, these are attacks from bladed weapons (such as axes), from blunt weapons (such as sledgehammers), and sometimes from motorized weapons, such as drills or saws. Motorized weapons are rare, though, as the noise and time required put the criminal at risk of unwanted attention from neighbors, an alarm system, or the police.

Ballistic protection is also helpful for a vault room, but not as important as it is with a panic room. The odds of a stray bullet hitting one object stored in the room is perhaps not a comparatively central concern. (On the other hand, a single shot hitting a human in a panic room is a critical problem.)

Another difference with constructing vault walls is that there typically is a greater focus on fire resistance. Flammability isn’t as crucial with a panic room: if there were a fire emergency, the client’s best bet is to exit their home, not to sequester themselves inside. With a vault room, clients want their valuables protected for an amount of time until emergency services can extinguish the fire. Cement, Ballistic Fiberglass, Kevlar, and some steels provide a generous amount of fire resistance. Plastic-based ballistic materials such as ultra-high-molecular-weight polyethylene and ballistic rubber are quickly engulfed in flames.

For clients with very important valuables, such as documents or jewelry, we advise placing these items inside low-security fire-resistant containers inside the vault room.

Modern saferoom walls utilize high-strength fibers that culminate decades of molecular research. Many of the materials were either first discovered for military use or invented accidentally – such as Kevlar, which was a happy accident of scientists looking to make more robust tires.

This material utilizes a network effect of interlinking fibers to provide enormous strength. Its molecular structure is a round (aromatic) shape, with massive numbers of hydrogen bonds between molecules. It works in the same way that a simple, thin, nylon net efficiently stops a speeding, solid baseball. Its flexibility is key to its success. Learn much more about the science behind ballistic Kevlar here.

Ballistic fiberglass works by utilizing glass strength while eliminating glass’s shattering risk by converting it to fibers. The fibers are interwoven and specially glued together to form numerous layers. The glass base of the fibers provides excellent fire resistance.