Benefits of Using Ballistic Kevlar Wall Panels

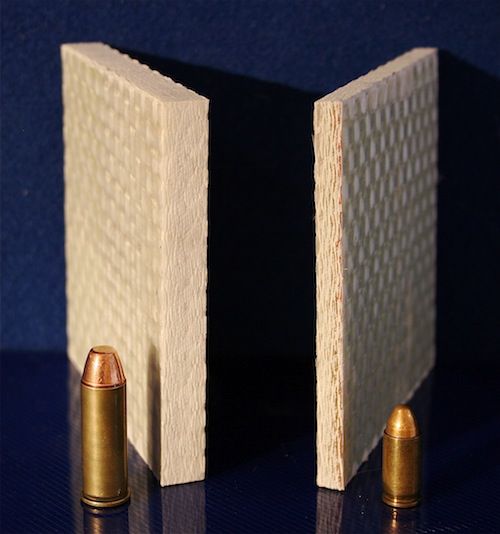

Investing in Kevlar panels provides high-level bullet resistance for your home or office in a lightweight and versatile way. Kevlar is a brand name for a type of para-aramid fibers known to provide: excellent strength to weight ratio, chord modulus, high tenacity, minimal creep, and about 3.5% elongation at break.Kevlar is often referred to as opaque armor or soft armor due to its extreme protective abilities.

Light Weight

Kevlar material is a surprisingly light bullet-resistant fabric. The low weight allows for convenient transport, minimal structural impact, and mobile practicality.

Convenient Installation

We offer Kevlar wall panels in 50″ by 96″ for easy application into commercial and residential walls. The flexible nature of the Kevlar panel allows for bending around non-flat surfaces.

History of Kevlar As Bullet Proof Fabric

The full name for the material branded as Kevlar is “poly para phenylene terephthalamide”, invented by a chemist working for Dupont in 1964. Kevlar was born out of the need for more efficient automotive tires in anticipation of a national gasoline shortage. Chemists there were attempting to create lightweight tires with additional durability. The inventor inadvertently concocted the polymer solution, and it was bound for disposal, but the chemist decided to test it.

To the team’s amazement, they found the fibers did not break, unlike nylon. Over the ensuing decades, applications found for this high-strength fiber increased exponentially, including its use as bullet-stopping armor.

Certified Ballistic Panels can protect against everything from battering rams to axes.

Our panels are optimized for safe rooms, conveniently installed, and rigorously secure.

They are certified to UL752 ballistic standards and offer Class IV forced entry resistance, one-hour fire resistance, storm projectile resistance, acoustic insulation, and much more.

How Kevlar Ballistic Panels Are Made

Kevlar is created through the chemical reaction of various monomers through condensation, resulting in liquid crystalline comportment. A mechanical process orients the polymer in an effective direction. Production requires sulfuric acid to keep the water-insoluble polymers combined in the solution during its synthesis. Production of the ballistic Kevlar fabric is expensive due to the challenges related to using concentrated sulfuric acid.

Types of Kevlar Panels

There is more than just one type of Kevlar material. It comes in a v

ariety of material types, each with different benefits, including:

Kevlar K-29: found in industrial applications, such as solid cables or vehicle armor.

Kevlar K49: found in essential cable and rope products.

Kevlar K129: features very high tenacity for ballistic applications, like ballistic panels.

Kevlar AP – Adds 15% higher tensile strength than K-29

Kevlar XP – lighter weight resin and KM2 plus fiber combination

Kevlar KM2 – enhanced ballistic resistance for armor applications

Risk Factors For Kevlar Wall Panels

Applications Bullet Resistant Kevlar

The application most well known is as a protective and bulletproof material. Para-aramids are a critical component in the personal protection in the US Army (as well as many other countries) in everything from combat helmets to ballistic vests. In helmets, the nature of the material helps stop bullets and refracts them to avoid cranial injury.

Its lightweight nature makes it convenient for soldier use. Kevlar ballistic panels are also used within armored vehicles and even some aircraft to prevent spall from explosive shells. Another popular application of Kevlar is in manufacturing bomb blankets. Its low weight allows civilians to carry it easily.

In addition to protection from bullets used by SWAT and military personnel, Kevlar is also used by firefighters for its high heat resistance.

Residential Kevlar Panel Installation

Kevlar sheets are effective in residential safe room applications. Contractors can conveniently add Kevlar panels to residential walls, fitting panels between the wall’s studs for high-level bullet resistance.

The low weight of para-aramid Kevlar ballistic panels – much less than other ballistic materials – makes them a good choice for bulletproofing doors and other moveable items.

There are some downsides to using Kevlar for armoring your safe room walls. While they stop bullets and knife attacks, they may not prevent all forms of forced entry attacks. Their flexible nature makes them susceptible to prying and possibly being pulled right out of the wall if another reinforcement isn’t present.

Like most ballistic materials, that they are opaque. With the right tools (our team can advise you), cut-outs can be made in the ballistic Kevlar sheets to make room for windows. Our custom bulletproof glass windows grant equal protection for these areas.

Get a free assessment and protect your home

Kevlar Fibers Vs Steel

As it’s stretching apart, you can see the steel wire is straightening out until abruptly snapping. The graph indicates the steel broke under 110 lbs of force.

The scientist next tests the ballistic Kevlar fabric. It behaves quite differently than the steel, almost like a taught ribbon while being pulled. As it fails, you can see the fibers popping, nearly one at a time – it fails in a different way to the stainless steel.

The graph shows the Kevlar doesn’t break until an impressive 440 lbs of force. Kevlar sheets can be manufactured with such toughness that it now has 8-9 times the strength of steel of comparative weight.

Why Choose Kevlar Panels for Reinforcement?

In all, ballistic Kevlar fabric and panels provide a wealth of options for securing a home, both during construction and afterwards. To learn more about conveniently protecting your home, please contact us.

Our expert team will guide you in the right application of opaque armoring for your home, whether it’s in the planning, construction or living phase.

Let Us Help You Protect

Your Home