FULLY CUSTOM

Custom Pocket Doors for Safe Rooms

Armored sliding door systems from $15,000

Up to 7 Layers of Pocket Door Armoring

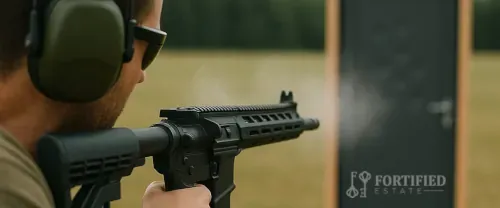

Stop Bullets, Even Rifles

With Millux ballistic steel discreetly infused inside, your armored pocket door and frame can be upgraded to stop dozens of powerful firearm rounds per UL 752 ballistic standards.

Level 3 Ballistic Upgrade

High-powered handguns, such as .44 magnum

Level 8 Ballistic Upgrade

Military Assault Rifles, Such As 7.62 Rounds

Resist Powerful Attacks

Our sliding doors are built based on the same structure as our powerful hinge doors which are independently tested to US Department of State standards for forced entry resistance.

High-Security Structure

Designed to resist an expert attacking for 1 hour

Ultra-Security Upgrade

Designed to resist an expert attacking for 4+ Hours

Weapon resistance includes axes, sledgehammers, battering rams, giant bolt cutters, etc. In addition, the ballistic upgrade enhances protection against concrete saws, plasma cutters, and more.

Bespoke Designs for Discreet Armoring

- Variety of Wood Species to clad your pocket door, from engineered woods to solid hardwoods.

- Hundred of Paint Finishes to classic RAL or paint match.

- Modern and Ornate door hardware options including door pulls and hardware colors

- Armored Glass and bulletproof glass options

- Unlimited Milling profiles and design layouts

- Personalized Design Process

Pocket door pricing from $15,000. Please contact us for a quote for your project.

Intuitive Sliding Door Operation & Installation

- Custom Sized to fit existing or new home

- Complete system: armored door slab, pocket frame, header track, multi-point lock system, cylinder, and more.

- Factory Assembled & Tested during manufacture

- Instant Vault Locking and unlocking for emergencies

- Effortless slide from specially engineered track system

- Motorization Upgrade available to remotely slide and lock your pocket door open and closed.

FREQUENTLY ASKED QUESTIONS

Our bulletproof sliding doors are most often made in pocket door style, where the frame is inside the wall, thought they can also be made as a double sliding door, where the moving door leaf overlaps the fixed panel when open. The latter option is most often done with glass sliding doors.

In the standard installation for our pocket doors, one side of our frame is first assembled. This frame is made of steel and connects all parts securely together: pocket framing, header (including track), and receiving framing (lock side). The armored door is then hung on the roller track. Finally the other side of the frame is put into place.

The frame overlaps the door on the top and both sides, allowing the door to be securely sandwhiched inside. The frame is then covered on all sides by normal wall. Alternatively, one side could have a wall, and the other side can have drywall directly attached to the pocket framing. Layers of ballistic wall paneling can also be used here.

Please reach out to us for more detail. Prior to most pocket door projects shipping, the factory will temporarily assemble the structure in the warehouse and photograph the process for ease of installation.

The typical timeline for a panic room pocket door creation is as follows:

- Shop Drawings: After the deposit is paid and we have the preliminary information, we can create the first shop drawings within 7-10 business days. It is up to the client and their team how many revisions they would like (3 included) and how much time they need for approval. We’ve seen approvals take anywhere from 3 days to 3+ months, and this is really in the hands of the client and/or their team.

- Production: Once drawings are approved, we go to production. Production and assembly usually take around 10 weeks for a sliding door, though it can take longer if the pocket door will have glass or motorization inside of it. In those cases production should be expected to take 12+ weeks. Of course, there is some variability due to the custom and high-security nature of manufacture.

- Shipping: Once production is complete and the product is crated we typically ship via air freight, and this takes around 2 weeks to arrive to the client’s destination.

Our high security sliding doors are custom to each client’s application. We provide a full system, from pocket framing, to door leaf, to sliding hardware, and much of it is pre-assembled. Pricing usually starts at around $15,000 with shipping included.

Pocket door price can be influenced by the following factors, starting with the largest impact:

- Motorization: if the pocket door will have a motor that actually slides the door open and closed, this is the largest impact on cost. However, this feature can be handy, as it can allow you to press a panic button from far away that will slide the door closed and locked.

- Security Level: we offer different armoring levels as well as bullet resistant steel upgrades for your panic room door

- Lock System: All doors have a multi point, powerful lock system integrated inside. The mechanical option is most common, but the door can be upgraded to have an electromechanical lock. If so, we can also include access control devices like keypads or biometric scanners.

- Design: The sky is the limit for design options on our custom sliding doors, from simple milling patterns in engineered materials to intricate designs in solid woods, like Oak or Mahogany. Typically though, when it comes to pocket doors, most clients prefer a subdued style.

Yes, with our motor upgrade for your high security pocket door, you can press a button to make the door sliding open and closed.

A heavy duty motor is installed into the wall above the pocket door which controls the door slide. If paired with electronic locking system, as we typically do, then a single button press can close and arm the door, even if you are far away.

There is a lot that goes into making our doors powerful!

Other people have attempted to make “simple” doors that rely on single sheets of metal to be thick and strong. This is good on paper, but in real life it is vulnerable to prying and forcing attacks.

Instead, we build ours based on real world attack standards. We have taken what we learned on US Dept of State testing for our hinged door models and applied it to pocket doors.

We use numerous layers of steel in a variety of shapes (for boxes to tubes) that repels all sorts of attacks from all sorts of angles, absorbing and distributing force, and even improving as an attack progresses.

The frame’s interaction with the door leaf is also crucial. We included an entire pocket frame system for stability and security. When closed, the door is tucked into the frame on three sides – leading edge, back edge, and top of door. This sandwich provides excelled protection.

This way the lock system merely needs to protect the door from being slide open, which is difficult to get leverage against.