FULLY CUSTOM

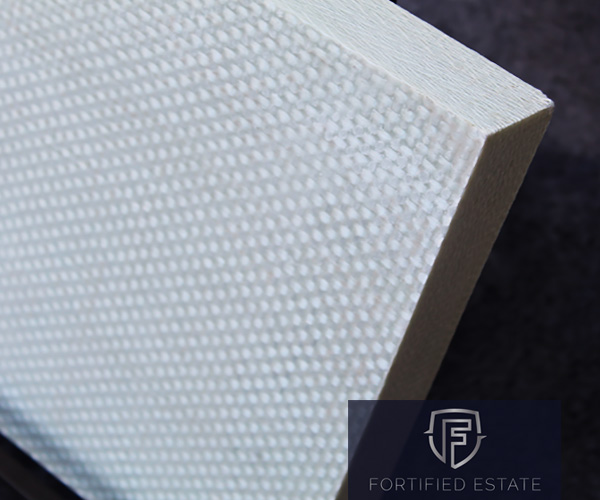

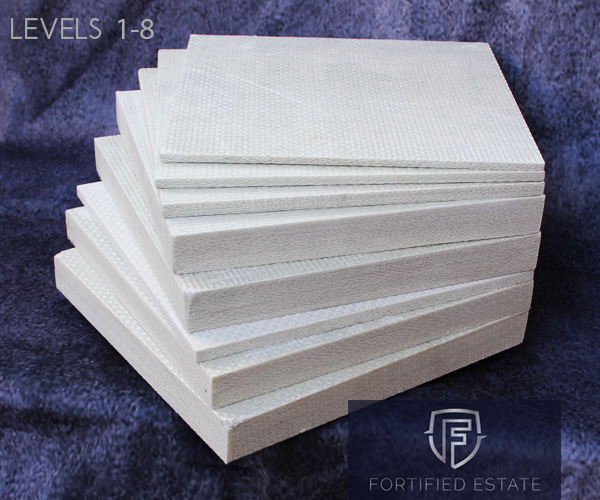

Bullet Resistant Fiberglass Panels – UL Level 1-8

Bulletproof fiberglass panels optimized for safe rooms with convenient installation.

UL 752 ballistics. Select levels tested for Class IV forced entry, 60-minute fire, and storm projectile resistance. Sound-resistant. Cellular and Wi-Fi signals pass through.

10 Year Warranty

Our materials and workmanship is warranted against defects for a period of ten (10) years from the date of receipt.We will repair or replace ballistic panels at our discretion, found upon our inspection, to be defective in material or our workmanship for up to ten (10) years from the date of receipt.

Ballistic TESTED

The bullet resistant panels are Underwriter Laboratory listed according to UL 752 Standards.

Redundant certification is also achieved under National Institute of Justice (NIJ) 018.01.

Beware of other manufacturer’s panels that are only self-tested by the manufacturer.

Please click on the chart for details on protection levels and panel weights.

FORCE ENTRY RESISTANT

Forced Entry Certified

These materials have been thoroughly tested to prevent body pass through against everything from battering rams to axes.

Levels 3, 4, 5, 7 & 8 tested according to Class IV ASTM F1233-98 Standards

Bulletproof Fiberglass Sizes and Protection levels

| Product | Firearm Protection | Bullets Per Square Foot | Thickness | Weight Per Square Foot |

| Level 1 Bullet Resistant Fiberglass | 9mm handgun | 3 | 1/4″ | 2.6 lbs |

| Level 2 Bullet Resistant Fiberglass | .357 Magnum | 3 | 5/16″ | 3.6 lbs |

| Level 3 Bullet Resistant Fiberglass | .44 Magnum | 3 | 7/16″ | 4.8 lbs |

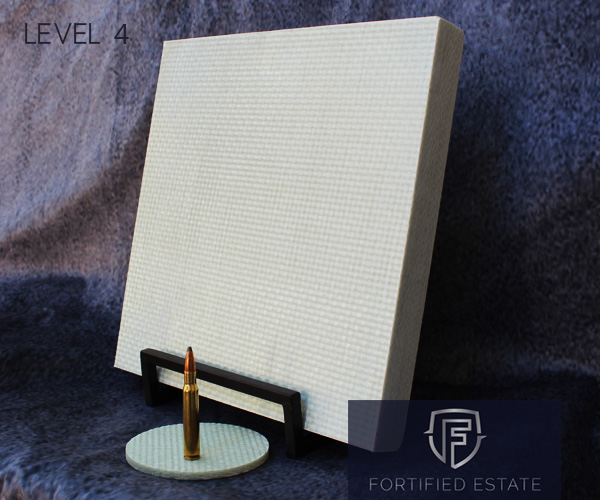

| Level 4 Bullet Resistant Fiberglass | .30 Caliber Rifle | 1 | 1-3/8″ | 13.9 lbs |

| Level 5 Bullet Resistant Fiberglass | 7.62mm Rifle | 1 | 1-7/16″ | 14.8 lbs |

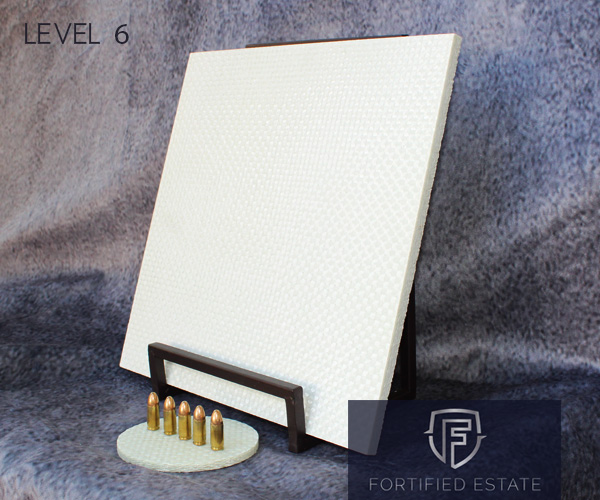

| Level 6 Bullet Resistant Fiberglass | 9mm submachine gun | 5 | 3/8″ | 3.9 lbs |

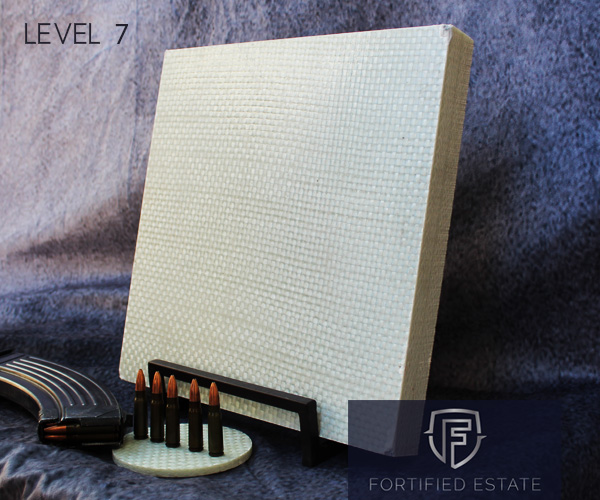

| Level 7 Bullet Resistant Fiberglass | 5.56mm rifle | 5 | 1-1/8″ | 11.7 lbs |

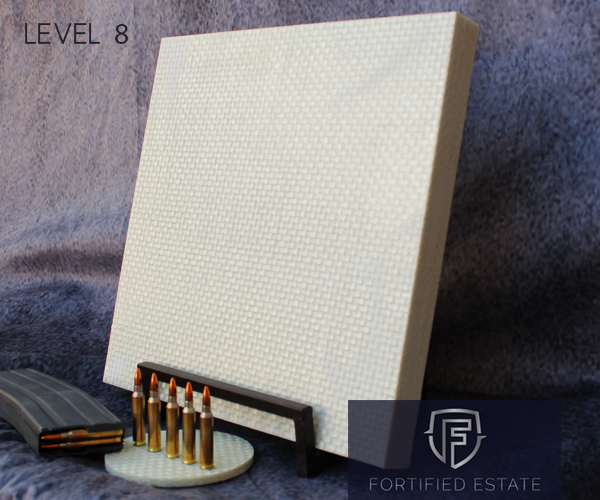

| Level 8 Bullet Resistant Fiberglass | 7.62mm rifle | 5 | 1-7/16″ | 15.2 lbs |

Standard widths available: 36″, 48″ and 60″

Standard heights available: 96″, 108″, and 120″

Standard batten strips available: 4″ wide x 96″, 108″, and 120″ high

Custom ballistic panel sizes and shapes available as required.

Performance Standards

- UL752 Paragraph 4.5 Standard for Bullet Resistant Materials – Levels 1-8

- National Institute of Ballistic Standards NIJ0108.01– Levels II – III

- One Hour Fire Rating Per ASTM E119-98

- Class IV Forced Entry Protection Rating Per ASTM F1233-98 – For Ballistic Panel Levels 3, 4, 5, 7 & 8

- R Value and Thermal Conductivity tested according to ASTM C-177

- Tested for acoustical properties AS-TL1734/5(a)

- Tested with projectile simulating F5 tornado at Wind Engineering Research Center at Texas Tech University

- Safety Data Sheet (SDS) available

Simple Install

Panels are large and conveniently sized to cover entire walls. They can easily be hid within a wall, or painted over. They can attach to standard wood or steel – even existing walls.

60 Minute Fire Rated

High security does not negate safety measures. These panels are officially tested to defer fire attacks for significant time.

60 minute fire and flame testing according to ASTM E119-98 protocols.

Extra Features

Our ballistic fiberglass panels are an exceptionally convenient method for creating highly secure walls doors and other barriers. They excel in many additional, functional areas.

Protection

- Storm projectile protection

- High heat and cold performance

- No electrical conductivity

- Non spalling

- Non ricocheting

Convenience

- Convenient sizes

- May be cut on site, too

- No radio or cellular signal blockage

- Low wicking – prevents mildew

- Non toxic – no fermaldehyde

Our Ballistic Fiberglass Installation Process

Bullet resistant panels are simple to work with: almost any contractor familiar with installing drywall can install a fiberglass bullet resistant panel, as well.

Attachment Methods

Most commonly, clients install ballistic drywall to walls with screws driven into wall studs, whether metal or wood. Self-tapping drywall screws are sufficient. If drywall is to cover the ballistic panel, then a complete screw pattern can be driver through both materials into the studs.

Installing Bullet-Resistant Fiberglass Panels In Existing Walls (Retrofitting)

Cutting Ballistic Panels

Large Cuts

A circular saw with a diamond grit blade is the typical way to make large cuts in a ballistic fiberglass panel. If making many cuts in thicker level material, you may need more than one blade for multiple panels. When cutting bulletproof fiberglass, ensure you follow proper safety protection, as summarized above.

Small Cuts (e.g. electrical cut-outs)

For smaller size cuts, such as for electrical outlets or pass-through drawers, a diamond grit saw blade on a reciprocating saw is a suitable method.

Seams And Corners

The seam formed by two panels meet could be a vulnerability in protection, but it is a very improbable one. Therefore, using a batten strip is ideal. About 40% of clients do so.

A batten strip is merely a 4″ wide post of the same material. The strip covers the seam, overlapping each panel by 2″. Strategically notching a spot in the bottom plate where the batten strips line up allows you to avoid creating an uneven wall surface. Also, make sure where your bullet resistant panels meet is offset from the location of vertical wall studs.

Where panels meet at a 90-degree angle, no extra protection is needed –so long that the panels overlap, as shown in the diagram to the right.

It is ideal to cover cut-outs, such as electrical boxes, with a small square of extra ballistic material that spans the length between two studs.

Safety Information

Contractors can cut bullet-resistant fiberglass to size, but – like all fiberglass – the material can irritate the skin.

When the ballistic material is sawed, drilled, or cut in any manner that creates dust, skin irritation can occur. Dust can irritate eyes, as well.

When creating dust from this product, wear a respirator mask, safety glasses or goggles, and protective clothing to avoid skin or respiratory irritation.

For general handling, such as moving bullet proof panels, we recommended wearing leather gloves to avoid irritation of fibers on hands.

AND, SECURE YOUR WHOLE PERIMETER WITH OUR:

Bullet Resistant Fiberglass Panel FAQs

- Measure the wall space to protect

- Determine potential threats and the resulting protection level

- Select a ballistic material, such as fiberglass or Kevlar

- Determine the optimal sheet sizes and batten strips to order

- Prepare tools you will need and review safety information

- Cut if required. Install and anchor paneling to wall studs

- Cover seams with batten strips for complete protection

- Paint or clad exposed ballistic panels if not inside the wall

A wall without specific ballistic reinforcement may offer next to no bullet resistance. Walls are primarily constructed from wood and drywall and offer insignificant protection. An exterior wall may provide some amount of benefit compared to nothing, but it still is often minimal. Most homes with masonry exteriors use brickwork for an aesthetic façade, meaning bricks are only single-layered.

A concrete, ICF, or double-layered brick exterior wall likely provides a fair bit of ballistic protection. However, due to the non-standard nature of such materials, specific bullet resistance levels are never definitive. Instead, using a certified and tested ballistic panel is highly recommended.

We’ve helped hundreds of clients conveniently armor their walls using modular ballistic materials. Contact us for expert help.

Various materials are available to create bullet proof wall panels due to decades of military advancement and chemical innovation. A summary of them is below:

Bullet Resistant Fiberglass Wall Panels

Bullet-resistant fiberglass is the most common material used for securing walls. It carries detailed ratings for ballistic resistance, is fire resistant and forced entry resistant. Builders can easily cut it on-site for proper installation. It does not interfere with cell signals and captures bullets without causing shrapnel productions.

Additionally, it is the most cost-effective bulletproofing option. Its downside is that it is heavier than softer materials, but this is not problematic for wall placement.

Kevlar Wall Panels

Kevlar is a well-known brand name of DuPont and is a para-aramid. Commonly called “soft steel,” the fibers are incredibly strong due to the many molecular bonds.

The benefit of Kevlar is that it is ultra-light and highly flexible; therefore, you can commonly find it in body armor. It is much less widely used as the material for ballistic wall panels because it is much more expensive than ballistic fiberglass, typically over 2-300% more. Kevlar also cannot stop rifle rounds at practical thicknesses.

However, there are cases where Kevlar panels make sense for armoring walls. One situation is where curvature is needed, for example, on a round wall or around a desk. Another use is when weight is essential. There are times where too much weight on a structure could lead to it being unsafe and collapse.

Fortified Estate is one of the only sellers of para-aramid ballistic Kevlar wall panels. Find more information about Kevlar panels here. We also use Kevlar in many of our ballistic blankets.

Steel Wall Panels

Ballistic steel wall panels, such as AR500, are traditionally thought of as the primary way to armor the walls of a room, but they present several problems and are rarely used for this purpose.

While steel can protect from all levels of firearm attacks, it is generally extremely heavy. Some steel materials, such as AR 500, have significantly reduced their weight compared to other steels. However, a bigger problem with steel to fortify a room is that it is very problematic to install. Unlike other methods, contractors cannot cut ballistic steel panels on-site. Installation is often either impractical or results in vulnerability due to nonprecise fit.

Unlike fiberglass and Kevlar, which absorb impact, steel may also produce shrapnel from impact and cause other risks and damage. Aside from protection concerns, if a safe room reinforced with steel will be frequently used (such as for a bedroom), it may lead to the occupant’s frustration with the resulting terrible cellular and internet reception. Poor reception is even more of a problem in an emergency while attempting to contact the police.

Concrete Walls

Poured concrete into masonry blocks with rebar support can provide high-level protection to a safe room, including forced entry resistance and some degree of ballistic protection. However, there are a couple of downsides.

Clients can only build this structure during a new home build. It’s undoubtedly impractical for a concrete truck to deliver concrete to the right spot in an existing building.

Additionally, because concrete walls are not standardized products, there’s no definitive way to know what specific firearm threats your walls will resist. Will they stop handguns but not rifles? How many bullets will they stop?

If someone has a concrete reinforced room, we recommend adding a low-level certified ballistic panel layer to ensure proper bulletproofing.

Ultra-High Molecular Weight Polyethelene (UHMWPE) Panels

Polyethelene panels are another option less popularly known but with good uses. They are similar to the benefits of Kevlar (lightweight and flexible) but much less expensive since they don’t rely on a branded material and don’t have sizing restrictions.

On the downside, they don’t have fire resistance like other options and melt quite easily. Lower ballistic levels are also more at risk of failure from simple forced entry attacks, such as knives.

There are popular derivatives of this material with brand names such as Dyneema and Spectra. UHMWPE is also commonly used in our ballistic blankets.

Ballistic Rubber Panels

When vulcanized rubber is manufactured thick and dense enough, it can effectively capture bullets. Like ballistic steels, there are no ballistic rubbers on the market that are certified to match specific ballistic standards, so it is a bit of a guessing game.

The material type is susceptible to fire, and builders rarely use it in homes or walls. It’s more typically of use in firearm ranges as a backing behind other ballistic resistant material.

A 4’ x 8’ bullet resistant fiberglass sheet starts as low as $320 and can range as high as $1,600, or $10 – $50 per square foot.

The price within that range depends on the UL protection level of the panel, ranging from protection from a few rounds of a 9mm handgun to multiple rounds of an M-14 assault rifle. Shipping is cost-effective compared to other heavy ballistic materials such as steel.

Other factors may affect pricing, such as bulk orders or special sizes and cut-outs. Standard panel sizes are: 3’ x 8’, 3’ x 9’, 3’ x 10’; 4’ x 8’, 4’ x 9’, 4’ x 10’; 5’ x 8’, 5’ x 9’, and 5’ x 10’.

Fiberglass bullet resistant sheets are so strong because they use the advantages of glass while avoiding its downsides. Fiberglass benefits from the solid tensile strength of glass but avoids its propensity to shatter.

It uses glass as fibers (hence its name) and then keeps all these minute fibers in place with a proprietary resin solution, leaving all the individual glass fibers secured. These complex interlocking patterns allow for extreme absorption of high impact force.

Multiple woven-roven layers combined through specialized heat press allow for creating various weights and thicknesses of bullet resistant panels. Our ballistic fiberglass reaches all eight UL 752 ballistic levels, protecting from 9mm handguns to AK-47s and from ax strikes to large explosions.

Despite its strength, ballistic fiberglass is easier to work with than other ballistic materials. Clients can cut it to size on-site with diamond grit saw blades and fasten it to walls with conventional materials. Such an easy installation is starkly in contrast to the complexity of installing steel ballistic options of all types.

While determining how much protection is needed is a personal choice, we can provide some rules of thumbs.

In an ideal world, one would purchase the highest level of protection available. But for most people looking at their potential threat level is more realistic.

The primary question is whether one feels protection from handguns is sufficient or requires protection from rifles. Handgun protection is much less expensive. The most common handgun level, level 3, protects from nearly all handguns, including the incredibly powerful .44 magnum. Also, at level 3, certification for ASTM forced entry resistance is achieved.

If looking at rifle protection, typical selections are Levels 7 or 8. Level 7 stops multiple rounds from standard assault rifles, such as the AR-15, and is the least expensive rifle level. For the ultimate protection, Level 8 provides resistance to even stronger assault rifles, such as the M-14.

Whether you need rifle or handgun protection depends on your perceived threats. Is your home one that criminals may target in a planned attack? Are you or someone who lives at your home well-known and possibly a personal target? Then protection from rifle rounds may be wise. On the other hand, clients primarily focused on safety from an opportunistic burglar will likely feel sufficiently protected with a Level 3 handgun-resistant panel.

Production of a client’s ballistic fiberglass panels typically takes 1-2 weeks.

Our ballistic fiberglass sheets are shipped directly from the factory to your shipping destination. Shipments can be sent to commercial or residential locations, though residential delivery adds some additional cost.

The bullet resistant panels are shipped LTL via shipping carrier on one or more pallets, depending on quantity. We can add a liftgate service to allow the removal of panels from the truck. If the client has a loading dock or forklift, the shipping company can skip this service.

For clients purchasing oversize bullet proof panels (such as with dimensions 5′ x 10′), the liftgate on the truck may be insufficient, and a forklift on site is needed. Once out of the truck, a pallet jack can be very convenient in moving the pallets closer to where they are needed.

Performance

- UL752 Paragraph 4.5 Standard for Bullet Resistant Materials – From Level 1-8

- National Institute of Ballistic Standards NIJ0108.01– From Levels II - IIIA

- One Hour Fire Rating Per ASTM E119-98

- Class IV Forced Entry Protection Rating Per ASTM F1233-98 - For Panel Levels 3, 4, 5, 7 & 8

- Low wicking – prevents buildup of mold

- Non toxic materials – no formaldehyde

Installation Details

In order to ensure a security even at butt-joints between two panels, a 4" wide batten strip of the same level material should be placed over these joints. These strips can be ordered from our company or can be cut on site from extra panels.

Battens are not required where a 90 degree corner occurs; one panel should simply overlap the other.

It is recommended to align panels to meet in between studs, rather than where they overlap. This avoids batten strips from needing to be placed in the same place as studs, thus minimizing wall thickness required.

In the case of electrical cut-outs, an additional 12” high piece of the same level of ballistic material may be installed from stud-to-stud, as close as possible to the hole

The most convenient option is to install panels within a wall; however, panels can also be easily attached the exterior of a wall that has already been built.

Panels may be attached using self-tapping drywall screws. When attaching a panel to a stud wall on which drywall will be the exterior surface, simply use enough screws to hold the panel to the studs, then come back with a complete screw pattern to the studs when hanging the drywall on top.

If connecting outside drywall service, simple drill through drywall to connect to wall studs.

Panels can also be attached with the use of adhesives. One product available is PL Premium Polyurethane Construction Adhesive. For stronger adhesion to non-porous substrates, such as aluminum, steel and stainless steel, or bonding one panel to another, a 2-part Methyl Methacrylate (MMA) adhesive may be utilized, such as Plexus MA 320.

If the panels will be on the outside of a wall or furniture, they can be painted to blend in with nearby walls and decor.

A clean surface free of grit and oily residue is required prior to gluing or painting panels. One method to achieve this finish is known as “peel ply.” At the request of the customer at the time of order, a peel ply layer can be used in the manufacturing process. This thin extra layer is removed in the field immediately prior to working with the product. This leaves a clean, very slightly textured finish ready for treatment.

Cleaning the panel can also be accomplished by wiping the surface with Acetone. Minimize the amount of time the panel is exposed to solvent, avoiding soaking.

Sanding is another means of preparation. 120-grit sand paper at medium pressure can be used to lightly “roughen-up” the surface.

Once fiberglass panels have been prepared with one of the above methods, they can be painted with either an oil or water-based paint. An automotive urethane works well as a “highend” solution. For any external application that requires panels to be exposed to the elements, a paint with a UV inhibitor should be used to protect the product from long-term UV ray exposure.

Though our standard listed panel sizes cover the vast majority of projects, our team can pre-cut panels to any two dimensional size preferred (additional fees may apply).

In the field, panels can also be cut on location with a diamond-grit blade. For example, TSD 180D, manufactured by Tenryu, is a quality 7” circular blade that can be use dfor this purpose.

For electrical boxes and other small openings, a diamond grit blade (available through most builder’s supply in the ceramic tile section) on a reciprocating saw should be sufficient.

In addition to wearing protective clothing, a fan can be placed behind the cutting area to help blow away fiberglass particles.

Warranty

Our materials and workmanship is warranted against defects for a period of ten (10) years from the date of receipt at the project site. We will repair or replace ballistic panels at our discretion, found upon our inspection, to be defective in material or our workmanship for up to ten (10) years from the date of receipt at the project site